Torus RV has 20 years experience in the production of vacuum sandwich panel caravan products, using GRP and XPS to now what is known as XPS Core System.

This has now been combined with true free-camping off-road use over the past 7 years and with rich 4WD experience and know how Torus RV have been able to mould a new product that will last for decades to come.

We also think that your product is only as good as the customer service your provide and this is something we pride ourselves on.

TORUS Build Technology

EXTERNAL:

2mm Gelcoat lined GRP skin for the toughest of cladding on the exterior that provides hail resistance. THE INNER CORE: 25mm High Density XPS Structural Foam with high density PU for walls and roof and 40mm for the floor

INTERIOR:

1.8mm Gelcoat lined GRP skin

EXTERIOR FLOOR:

Reinforced Woven Matt for structural strength and impact resistance.

FIRE RESISTANCE:

B1 - Very difficult to ignite

FIRE INSULATION:

R3 This product offers around 3 times the thermal insulation as a standard product.

SOUND:

The insulation also make the product have sound insulation as well.

- Wall Thickness: 30mm

- Roof Thickness: 30mm

- Floor Thickness: 50mm

Walls, floor and roof are all made in one peace providing strength and less joints for water ingress. They are created using a vacuum system that bonds all the layers together with two part Sika Force polyurethane glue. Once bonded you can span the panels stand in the middle of them and they will bend and flex and once you get off they will return back to the original position opposed if you did this to a wood framed wall it will bend and come back but not to the original and for an alloy framed wall it will stay bent. What this does is give you a product that wants to maintain its original shape and position.

Roof

All caravan manufacturers make flat roofs, they all sag and dip under there own weight when it rains water pools around roof hatched and air conditioners, so XPS Core System created a vacuum mould that has 4 degree curve so after 150 minutes the roof panel sets and then has a dome shape forcing the water away from the centre of the roof.

Final Product

Once all the panels are joined together they act as supports for each other and the product becomes like a monocoque body, and then end result is the strongest caravans ever built making them the ultimate build tech for off-road caravans.

Benefits

- Hail Resistant

- Two times the strength of any framed van, 10 year Structural Warranty

- Three times the insulation of a standard caravan, very efficient to heat and cool and perfect for the extremes of Australia.

- Dome structural roof, yes you can walk on the roof.

Testing

All individual body panels are oven tested at 65c for 3 hrs to cure the skins and glues and also check for any delaminations or bubble once the pass this test then these parts are then approved to be used on a caravan.

Once the full caravan is finished then we oven test the whole van at 65c for another 3 hrs to re-test the body shell and test the other glues and laminates in the van.

Internal Fitout

Most caravans have been made the same way internally and externally for the past 50 years.

With furniture looking shiny and modern but when you look closely you can see that this in generally a box with a hole cut out and a door screwed on the front, this went out with the one tap kitchens of the 30s and 40s and no one would accept this in there house and we don’t think caravaners should accept this either.

We use marine plywood and all furniture if flush fit and computer design with strong quality hinges and marine plywood used throughout. We use modern pantry and storage systems.

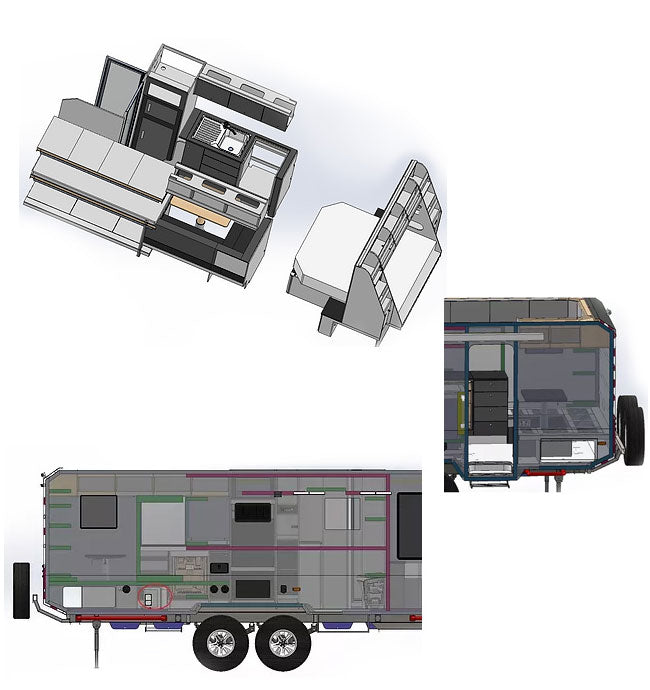

Our products are 100% drawn in 3D SolidWorks before we make them, allowing us to foresee issues in design and allows accuracy in parts and material development, our furniture makes use of the same systems allowing us the use CNC based production of the whole furniture providing quality and accuracy in every build, giving our customers the assurance of consistent product.

We use a 6" / 150mm hot dipped galvanised chassis, that all caravans rely on this to provide there structural rigidity we have this but also have a structural 50mm bonded floor providing an immensely strong.

We have two main types of suspension Rocker Roller Leaf Spring for or semi-off-roads or KODIAK Trailing Arm Coil Spring with Nitrogen Gas Struts for our off-road caravans.

Water Tanks

All our products use the off-road poly tanks we do not use the cheap rotor moulded thin tanks, plus we add gal plate protection